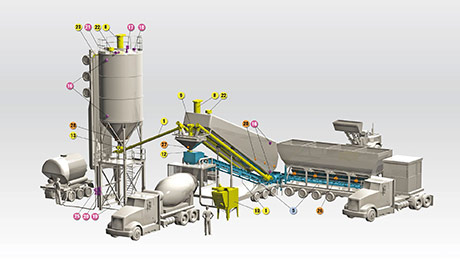

Concrete Batching Plant Layout

Concrete batching plant layouts can vary significantly based on factors such as site constraints, production requirements, and the type of batching plant being used. However, here are some common details found in concrete batching plant layouts

- Aggregate Storage Bins: These are where various aggregates such as sand, gravel, and crushed stone are stored before being used in the mixing process. They can be arranged in various configurations depending on the plant's capacity and layout.

- Cement Silos: These tall, cylindrical structures store cement powder before it's mixed with other ingredients. The number and size of silos depend on the production capacity and the types of cement being used.

- Mixing Unit: This is where the ingredients are combined to produce concrete. It typically consists of a mixer, which can be a stationary drum mixer or a twin-shaft mixer, depending on the plant's design.

- Water and Additive Storage: Tanks or containers for storing water and additives, such as admixtures or coloring agents, are often included in the layout.

- Conveyor Systems: These systems transport materials such as aggregates, cement, and additives to the mixing unit. They can be belt conveyors, screw conveyors, or pneumatic systems, depending on the plant's design.

- Control Room: A control room houses the plant's control panel and operator interface, where the batching process is monitored and controlled.

- Weighing and Batching Equipment: Load cells or weighing systems are used to measure and batch the ingredients accurately before they are mixed.

- Storage Areas: Space for storing additional materials such as spare parts, tools, and maintenance equipment is often included in the layout.

- Access Roads and Paths: Adequate access roads and paths for vehicles and personnel are essential for safe and efficient operation of the plant.

- Safety Features: Safety features such as barriers, fencing, and warning signs should be incorporated into the layout to ensure the safety of workers and visitors.

Overall, a well-designed concrete batching plant layout maximizes efficiency, productivity, and safety while meeting the specific requirements of the construction project.